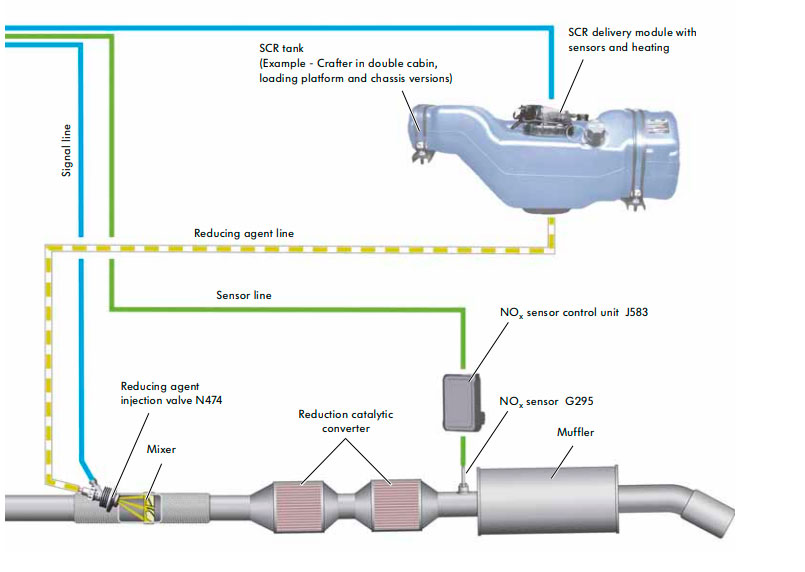

The reduction catalytic converters convert the nitrogen oxides (NOx) contained in the exhaust gas into nitrogen (N2) and water (H2O). To achieve this a reducing agent is continuously injected into the flow of exhaust gas before the reduction catalytic converters. The reducing agent is stored in a separate additive tank.

The system is controlled by the engine control unit J623 in conjunction with the NOx sensor control unit J583 and the sensors responsible for the system.

The essential components will be explained at the end of this system overview.

Overview of SCR system

The SCR system comprises the following main areas:

- Reducing agent

- Tank system

- Delivery system with heating

- Reducing agent injection and distribution in exhaust flow

- Reduction catalytic converters and measuring / control components

A brief overview of these areas is provided on the following pages, in the order of the actual process, starting with the tank system.

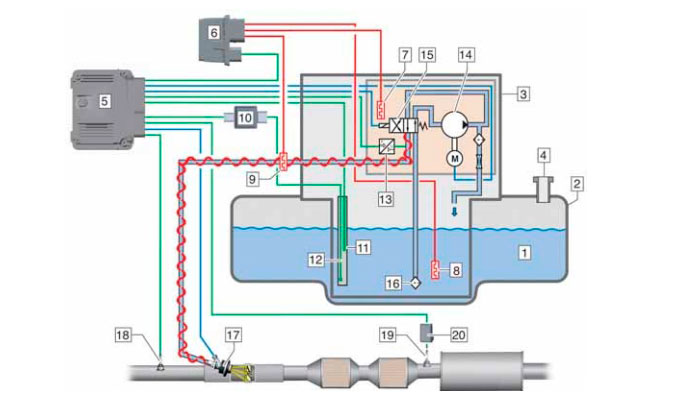

1 - Reducing agent

2 - Reducing agent tank

3 - Reducing agent delivery module

4 - Filler

5 - Engine control unit J623

6 - Reducing agent heater control unit J891

7 - Reducing agent pump heater Z103

8 - Reducing agent tank heater Z102

9 - Reducing agent line heater Z104

10 - Reducing agent level evaluation unit G698

11 - Reducing agent level sensor G697

12 - Reducing agent temperature sensor G685

13 - Pressure sensor for reducing agent metering system G686

14 - Reducing agent pump V437

15 - Reducing agent reversing valve N473

16 - Filter

17 - Reducing agent injection valve N474

18 - Exhaust gas temperature sensor 3 G495

19 - NOx sensor G295

20 - NOx sensor control unit J583

AdBlue® reducing agent

The ammonia necessary to reduce the nitrogen oxides is not used in a pure form, but in the form of an aqueous urea solution. Ammonia in its pure form has an irritating effect on skin and mucus membranes and also has an unpleasant odour. The reducing agent used in the SCR system is a liquid that is referred to by the automotive industry by the standard brand name AdBlue®.

AdBlue® is a high purity, transparent 32.5% solution of urea in water. It is manufactured synthetically.

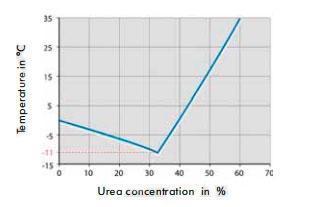

Freezing point of AdBlue

Freezing point of AdBlue

AdBlue® has a urea content of 32.5 %, because the reducing agent has the lowest freezing point at this mixing ratio.

Properties of AdBlue®:

- AdBlue® freezes at temperatures below –11 °C.

- AdBlue® decomposes at high temperatures (approx. 70 °C - 80 °C). The consequence of this is that ammonia is formed, which can cause an unpleasant odour.

- Impurities caused by foreign substances and bacteria can make AdBlue® unusable.

- Leaked and crystallised urea creates white spots. These spots can be cleaned with water and a brush (immediately if possible).

- AdBlue® has a high creep capability. Electrical components and connections must be protected against the ingress of AdBlue®.

Instructions for handling AdBlue®:

- Only AdBlue® complying with the approved manufacturer's standard from original vessels is to be used.

- Drained AdBlue® may not be reused, to prevent impurities.

- The reducing agent tank is only to be filled using containers and adapters approved by the manufacturer.

- The reducing agent can irritate skin, eyes and the respiratory system. If this liquid comes into contact with the skin, wash it off immediately with plenty of water.

If necessary, seek medical advice.

The tank system

The tank system

Depending on the Crafter version - panel van/Kombi or loading platform/double cabin - the tank system differs in terms of the positioning of the tank, the shape and the filling connection.

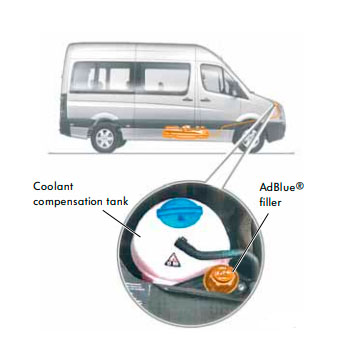

AdBlue® tank for panel van/Kombi

The AdBlue® tank for the closed Crafter panel van/Kombi design is positioned below the body platform.

It has a capacity of

- Standard design b approx. 25.3l

- Cold country design b approx. 18.5l

The filler is located on the right of the engine compartment close to the coolant compensation tank.

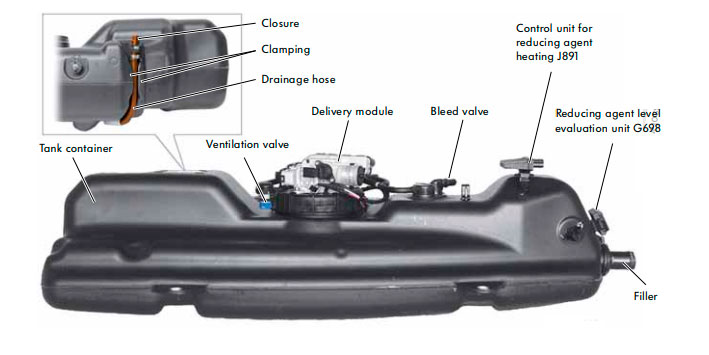

The tank is emptied using a drain hose, which is clamped into the rear of the tank. To empty the tank, the hose is detached from the clamp and bent downwards. To open the drainage hose, the closure must be unlocked and detached.

Rear of tank with drainage hose